Project Summary

Customer

Municipal Authorityof Westmoreland, PA

Type of Project

Adding PAX Mixing Systems and Powervents® to storage tanks in the distribution system to improve water quality and meet regulatory compliance.

Results

- Reduced disinfection byproducts (DBPs)

- Maintained chlorine residual

- Prevented stratification in summer

- Prevented icing in winter

Westmoreland County is located in Pennsylvania’s Laurel Highlands, 30 miles southeast of downtown Pittsburgh and within 200 miles of major metropolitan areas like Baltimore, Cleveland and Washington, D.C. It is home to major companies like Kennametal, Elliott Group, Philips Respironics and Siemens. And it boasts a number of tourist attractions like Fort Ligonier, Historic Hanna’s Town, West Overton Village and Bushy Run Battlefield.

The Municipal Authority of Westmoreland County (MAWC) provides water service and wastewater treatment for 125,000 of the county’s 350,000 residents, maintaining over 70 water tanks and three water treatment plants. In 2016, the authority launched a $130 million reinvestment program, including a water quality proactive initiative.

Staying proactive

The county has always been very proactive in maintaining the quality of the drinking water it delivers to its customers.

As a result, the authority has always been in compliance with water quality standards enforced by the Pennsylvania Department of Environmental Protection (DEP).

However, MAWC recognized that those standards are constantly changing. And the authority wanted to make sure it complied with the regulations and avoided the fines and other sanctions DEP could impose if it didn’t.

“

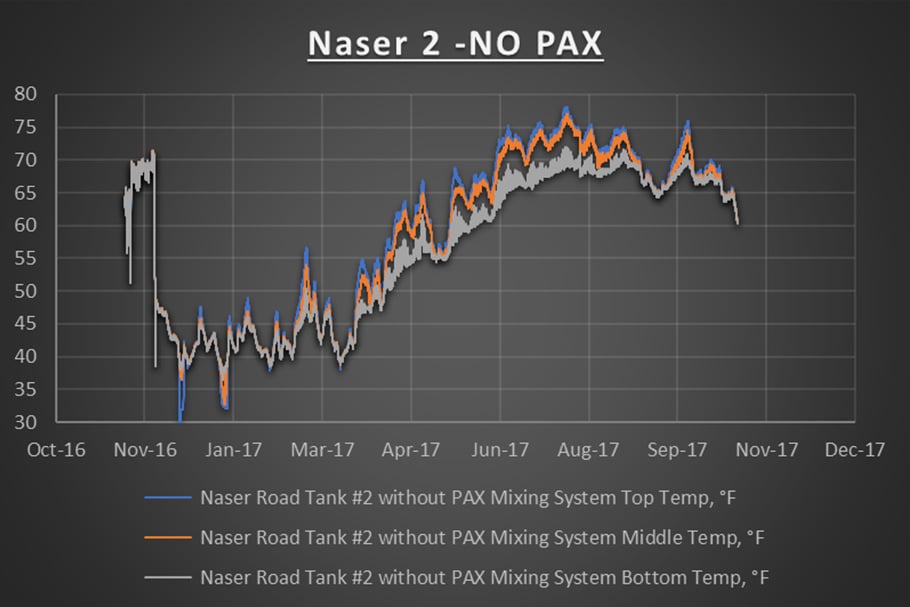

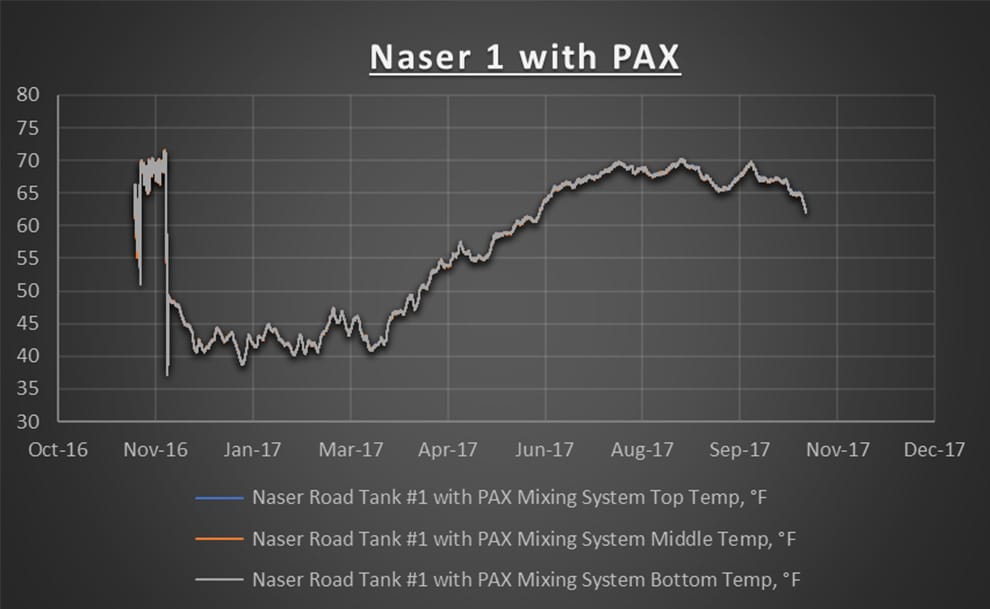

The main issue the authority needed to deal with was stratification of the water in the tanks. A yearlong test showed that temperatures varied by 10 degrees from the top of the tanks to the bottom, enough to cause problems.

— John SmithDan Frum, Water System Consultant, USG Water Solutions

USG Water Solutions (USG) proposed the installation of a PAX mixer to circulate water inside the tank and treat the entire volume, adding PAX Mixing/Powervent® combo systems to remove disinfection byproducts like trihalomethanes (THM) that accumulate in the tank headspace as the chlorine reacts with naturally occurring organic matter. After performing a yearlong test, the utility realized that the PAX Mixing/Powervent combo installed by USG maintained a constant temperature equilibrium throughout the tank, keeping chlorine levels consistent and maximizing THM removal while minimizing cost.

Standardizing the approach

After a brief trial, the authority standardized the PAX Mixing/Powervent combo solution and has equipped 30 of its 70 plus tanks with the updated technology. It plans to update the remaining tanks in the next few years.

As a result of the changes, the authority is providing better service and better water quality, while meeting DEP standards for minimum chlorine residual now and in the future.

In fact, the American Water Works Association recently recognized the authority for having the best tasting water in Pennsylvania.

“

This combined solution helps maintain a consistent residual disinfectant level along with a reduction in water age in our large regional storage tanks. It has also decreased disinfection byproducts.

— Mark Stoner, Water Quality Superintendent